Keep up with what’s new.

Connect with us on LinkedIn for news, insights and related topics.

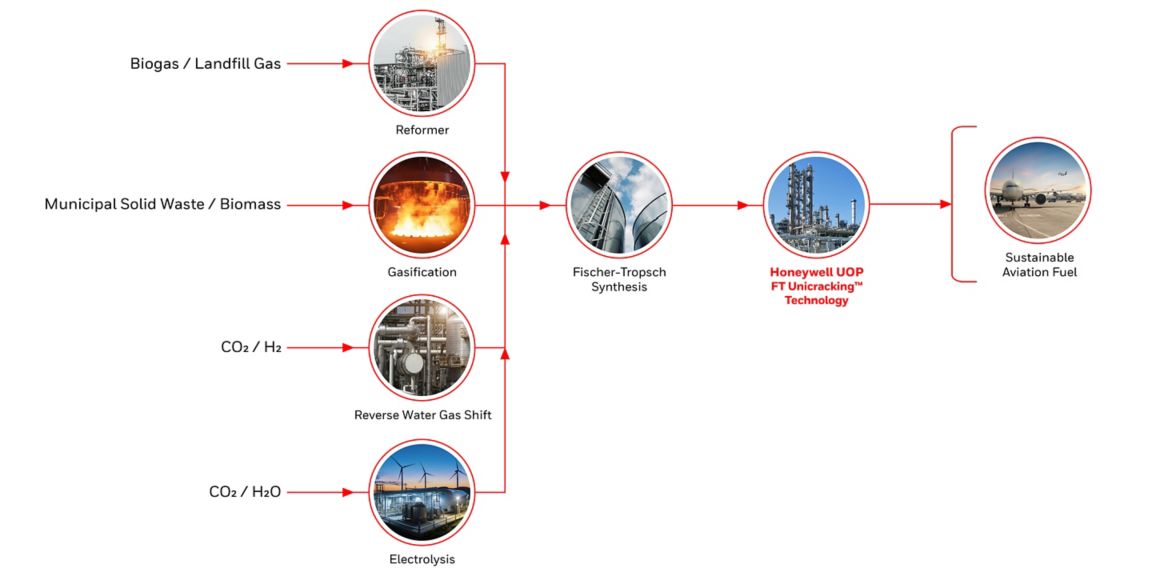

Honeywell's new FT Unicracking™ technology converts Fischer-Tropsch liquids and waxes from waste into ASTM-approved sustainable aviation fuel (SAF).

Talk To an expertLeading the way in Fischer-Tropsch (FT) hydrocracking technologies, Honeywell's new FT Unicracking process uses a combination of proprietary, commercially proven, highly selective hydrocracking and hydroisomerization catalysts to produce 3-5% more sustainable aviation fuel (SAF)1,2, reduce by-product waste and achieve up to 20% cost reduction compared to other commonly used FT-hydrocracking methods.3,4 FT Unicracking, which can be used both for new units or retrofits, is Honeywell’s latest addition to its Renewable Fuels technology portfolio consisting of the industry leading Ecofining™ suite of solutions, Ethanol-To-Jet and UOP eFining™ (Methanol-to-Jet).

FT Unicracking converts liquids and waxes from multiple waste sources into Fischer-Tropsch Synthetic Paraffinic Kerosene (FT-SPK) which is a form of SAF that has been ASTM D7566 approved since June 2009. Viable feedstock sources for FT liquids and waxes include agricultural and/or forestry waste, municipal solid waste, biogas and/or landfill gas, and CO2 combined with hydrogen. FT Unicracking is expected to significantly contribute to meet the growing SAF demand, as a flexible, highly selective, ASTM-approved pathway to SAF. It is a ready-now solution producing a lower carbon SAF product resulting in a high bankability score.

![]()

Higher SAF yield

Produce 3-5% more SAF2,3

![]()

Lower CAPEX

Enable a cost reduction of up to 20%3,4

![]()

Less waste

Reduce by-product waste streams

![]()

90% less carbon intensive1

Process waste biomass

As a trailblazer in renewable fuel technology, Honeywell UOP enables broad flexibility of feedstock supplies for sustainable aviation fuel, diesel and other renewable fuels. Leveraging over 70 years of design and operational experience in hydrocracking and over 30 years of design experience in FT-hydrocracking, Honeywell UOP’s FT Unicracking process is the latest in a line of technologies driving decarbonization in the aviation sector. Honeywell UOP offers multiple routes to market using a variety of feedstocks, including Ecofining (utilizing fats, oils and greases), ethanol-to-jet, UOP eFining (methanol-to-jet). Now FT Unicracking supports pathways for biomass to liquids (BtL), gas to liquids (GtL), waste to liquids (WtL) or power to liquids (PtL) by converting Fischer-Tropsch liquids and waxes into ASTM-approved SAF.

While Honeywell is an industry leader in methanol to olefins processing with demonstrated oligomerization and hydrogenation technologies, our unmatched commercial and R&D experience and commitment to creating a sustainable future also extend to the following areas:

1Carbon intensity is based on ICAO CORSIA default lifecycle emissions values for CORSIA-eligible fuels, Table 1 - agricultural residues and forestry residues. Corsia Eligible Fuels - Life Cycle Assessment Methodology - Version 5 June 2022.

2By utilizing proprietary SAF selective Honeywell UOP hydrocracking and hydro-isomerization catalysts.

3By utilizing a Honeywell patent pending process configuration.

4Based on internal UOP cost (Estimated Erected Cost) analysis that compares a typical configuration with the patent pending configuration.

Connect with us on LinkedIn for news, insights and related topics.

Did you know that your internet browser is out of date?

Your browser is out of date, and may not be compatible with our website.

Just click on the icons to download a compatible browser.

By closing this window you acknowledge that your experience on this website may be degraded.