Keep up with what’s new.

Connect with us on LinkedIn for news, insights and related topics.

In collaboration with Honeywell UOP and Qpinch, Qpinch Heat Transformer (QHT) offers an innovative solution which combines efficiency and flexibility. This unique combination allows the technology to be integrated into just about any site. It transforms waste heat into upgraded valuable process heat, with very little electricity consumption, providing the best financials within its technology category.

(*) If the upgraded heat is used to offset heat input derived from the combustion of fossil fuels this can result in a positive impact on one’s CO2 emissions.

![]()

Capture Waste Heat

Excess steam, condensing vapors and hot process liquids contain an abundance of residual energy that is normally released into the atmosphere instead of recovered. The QHT can upgrade waste heat at temperatures as low as 80°C.

![]()

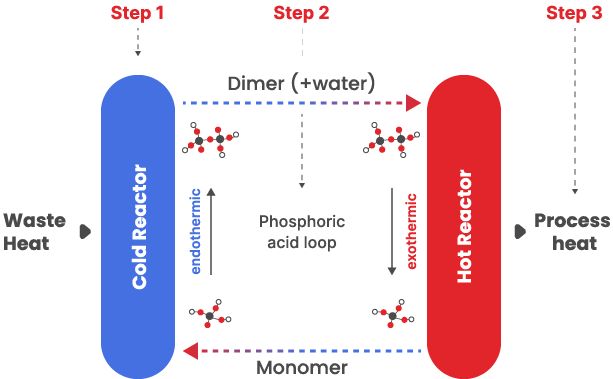

Transform Waste Heat

The captured low temperature waste heat can be transformed into a higher temperature process heat, using a physicochemical reaction. Very little electricity is needed to drive the temperature lift.

![]()

Deliver New Energy

50% of the residual heat is recovered and transformed into a new process heat with a temperature lift up to 100 °C, depending on the source’s waste heat temperature.

Join us for an exclusive webinar hosted by Honeywell UOP & Qpinch with Hydrocarbon Processing. Discover innovative technologies and smart alliances that are set to revolutionize waste heat recovery. This is your chance to learn directly from industry leaders and visionaries about the latest advancements and business models that will shape the future. Join us for an exclusive webinar hosted by Honeywell UOP & Qpinch with Hydrocarbon Processing. Discover innovative technologies and smart alliances that are set to revolutionize waste heat recovery. This is your chance to learn directly from industry leaders and visionaries about the latest advancements and business models that will shape the future.

watch now

Latent heat recovery is advancing industrial energy efficiency by capturing and repurposing heat that would otherwise be lost. In many processes, significant energy is wasted through hot exhaust gases or excess steam. By harnessing this latent heat—energy stored during phase changes such as condensation—industries can dramatically reduce energy consumption, operating costs and carbon emissions if the upgraded heat is used to replace the combustion of fossil fuels.

With rising energy prices and increasing pressure to meet sustainability goals, latent heat recovery is becoming a strategic priority aligned with energy efficiency and decarbonization. Companies in energy-intensive sectors are recognizing that improving heat recovery isn’t just about cost savings—it’s also about long-term competitiveness and resilience against energy market volatility.

Integrating latent heat recovery enhances process efficiency and operational stability. By reducing reliance on external energy sources, companies can mitigate supply chain risks and improve energy security.

Minimal Maintenance: A Qpinch Heat Transformer is built with industry-standard components that uses no compressors, making the installation highly efficient and with low-maintenance requirements.

Safety Compliance and Sustainability: The QHT complies with strict industry safety regulations, and is a proven technology backed by 14 years of research and development. The QHT operates without chemical consumption or use of catalysts. As a bonus, the implementation of heat recovery systems may qualify plants for incentives, credits or certificates.

Flexible Technology: The QHT can cope with a wide range of temperature fluctuations, operating from 10% to 100% of design duty, all with limited need for operator intervention. The technology allows for the combination of multiple heat sources and varying output temperature.

Low OpEx - High Yield: The combination of marginal electricity requirements and low-maintenance demands of the QHT, results in the most efficient process steam output for the money invested: a maximum 40kW of electricity per MW steam.

Modular construction is transforming the industrial landscape by offering faster, more cost-effective, and scalable solutions. By constructing pre-engineered modules offsite, companies can significantly reduce installation time, minimize disruptions, and ensure higher quality through controlled fabrication. This approach is particularly valuable in energy-intensive industries, where efficiency, reliability, and rapid deployment are critical.

Honeywell UOP and Qpinch solutions offer enhanced energy efficiency, lower CO2 emissions (when the upgraded heat is utilized to offset fossil fuel combustion elsewhere in the facility), and reduced operating costs. As industries pursue sustainable and high-performance solutions, Honeywell UOP is enabling a new benchmark for efficiency and innovation, guiding clients toward a more energy-efficient future.

Get in Touch with our technical experts