Keep up with what’s new.

Connect with us on LinkedIn for news, insights and related topics.

Proactively monitor your adsorbent units with real-time data

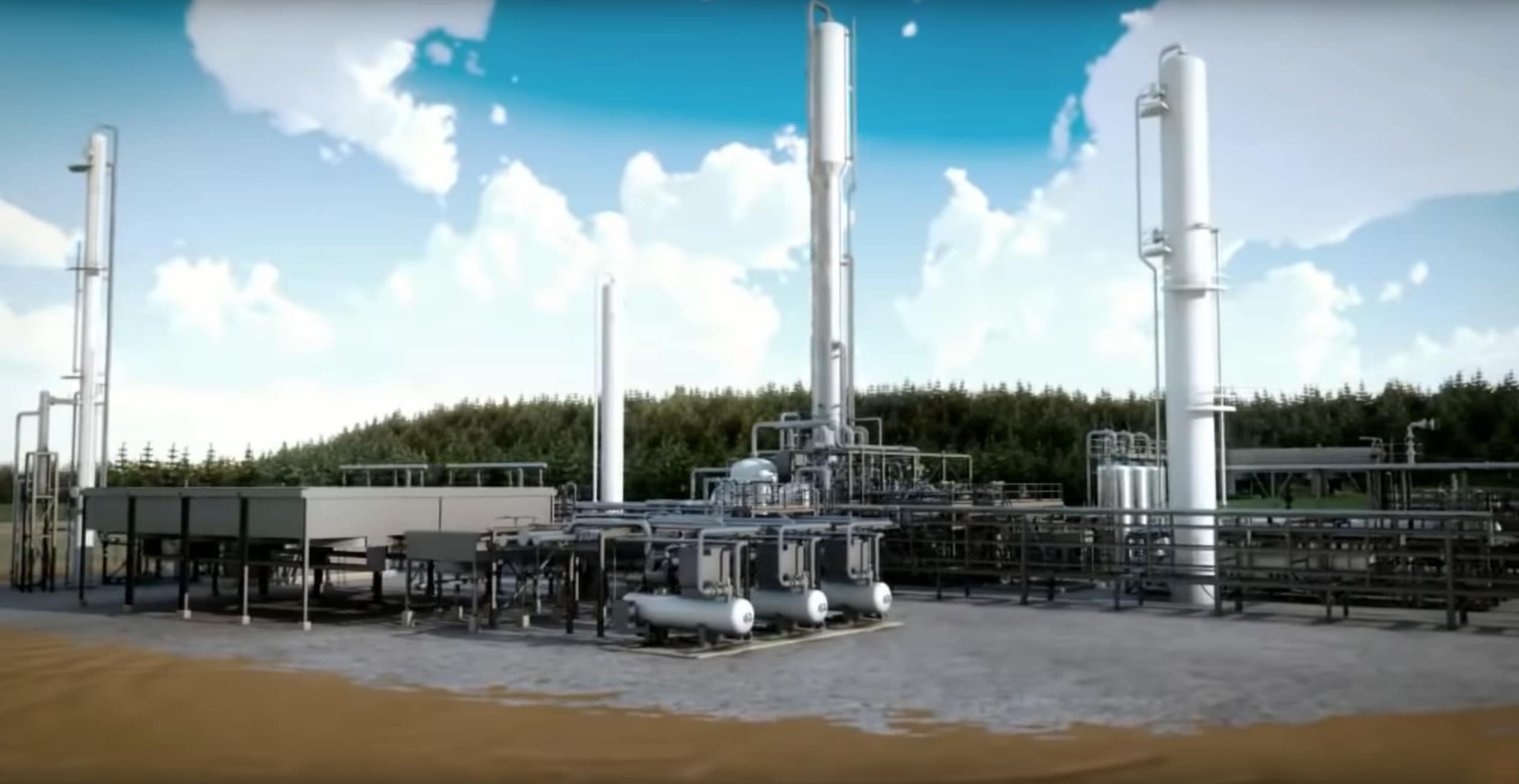

Untimely plant shutdowns, equipment failures, inefficient operations and poor performance can cost you time and money. The UOP ARMGuard™ system effectively monitors your adsorbent unit performance with real-time insight to help ensure that your unit is running efficiently and reliably.

ARMGuard™ is a software-based remote monitoring system that uses the existing instrumentation in your plant to help you optimize your adsorption cycle, reduce energy consumption, confidently operate at variable feed conditions and, most importantly, reduce costs by mitigating unscheduled shutdowns.

The UOP ARMGuard™ system can help:

Evaluate your treater for better reliability and predictability

The typical catalytic reforming units’ change-out process of chloride adsorbent beds is usually based on either historical experience or the recommended frequency in the original design specs. Neither approach considers changing dynamics of inlet chloride levels and may lead to change outs that happen too soon or too late … resulting in lost investment dollars, adsorbent waste and inefficient man hours.

UOP’s ChorideGuard system uses real-time catalytic reforming unit process conditions to evaluate and monitor chloride treater operations, delivering:

Hydrogen is essential to the operation of today’s refineries and petrochemical complexes. The efficient use and availability of hydrogen within the plant has a direct impact on profitability.

Rely on PSAGuard™, Honeywell UOP’s newest software solution, to continuously monitor and analyze unit operations, to help make data-backed decisions and to take action that may improve unit performance. PSAGuard taps the power of Honeywell Connected Plant technology to help you optimize and improve the reliability of your Honeywell UOP PSA units, enabling maximum profitability through efficient hydrogen management.

Connect with us on LinkedIn for news, insights and related topics.

Did you know that your internet browser is out of date?

Your browser is out of date, and may not be compatible with our website.

Just click on the icons to download a compatible browser.

By closing this window you acknowledge that your experience on this website may be degraded.