Keep up with what’s new.

Connect with us on LinkedIn for news, insights and related topics.

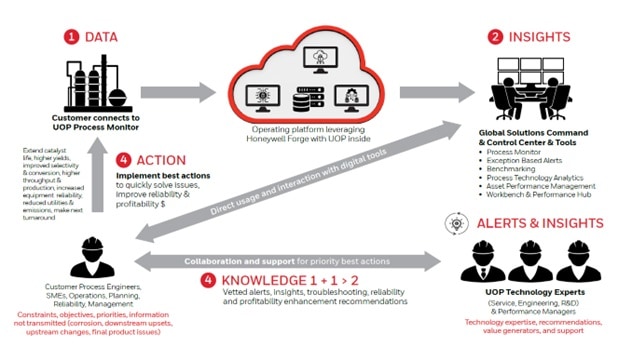

Performance+ Services ensure sustained benefits by providing expert support from Honeywell UOP to achieve operational excellence.

Request A consultationThis digital service improves unit efficiency and reliability by offering operational visibility, identifying performance gaps, and providing real-time recommendations. With priority access to UOP technical experts, you can enhance unit reliability, production rates, efficiency, and profitability. Our proactive service addresses process issues, equipment failures, and performance optimization, offering dedicated expert support to solve problems and manage changes promptly, transforming your teams from reactive to proactive.

When built for Honeywell UOP licensed units, Honeywell UOP Performance+ Services offers an integrated suite of tools to enable your team to monitor, model, predict, and optimize to drive more value out of your operations:

Process Technology Analytics and Process Digital Twins: PTAs and PDTs update the gains, limits, and setpoints to the APC on a regular basis to keep the APC evergreen. For complex or site level optimization, UOP can offer the Plantwide Optimizer which is based on the patented proxy limit technology and can provide effective coordination and optimization across multiple process units and downstream blending if applicable.

Advanced Process Control: UOP’s experience and know how is built into every APC application. UOP design correlations are encapsulated in toolkits that capture the non-linearity of the process units and calculate variables that are difficult to measure directly using other measurements. This allows the APC application to push the process unit closer to its limits.

Operator Training Simulators: High fidelity operator training simulators (OTS) for the key process units with embedded UOP reactor models, scenarios and exercises and Abnormal Situation Management Consortium (ASM) compliant graphics that match the DCS graphics to train the operators in a safe environment well before plant start-up. These operator training simulators leverage UOP’s process design models and can also be used to test out control strategies for the distributed control systems (DCS) and develop seed models for the Advanced Process Control (APC)..

Asset Performance Management: Honeywell’s Asset Performance Management software provides continuous process performance monitoring and equipment health surveillance covering every aspect of the plant from instruments, valves, and compressors to an entire process unit. The software enabled with AI/ML techniques, UOP know-how (for UOP designed and delivered equipment and modular units) and /or vast OEM correlation database offers performance and fault models to detect and predict equipment health and process performance issues to help avoid unexpected plant downtime.

Best in Class Training and Simulations: A team is only as good as their knowledge and skills. Prepare your team to perform their jobs accurately and safely with flexible competency solutions from an industry leader in refining, petrochemical and gas processing technologies. UOP’s training and simulations offer the in person and on demand tools you need to address the growing skills gap while helping to increase productivity and reduce the risk of human performance issues at your plant.

UOP has a tenured history of implementing profitable connected industrial solutions. UOP manages digital transformation solutions with over 350 service agreements customers operating refining, petrochemical and gas processing plants with most customers renewing over the last 70+ years. We have over 310 units connected at over 100 customer sites globally with plans to connect to 750+ units within a year with our digital tools deployed. We have been proactively providing support with limited data sets for decades. Extract the most value with Performance+ Services that leverage the best of our technical expertise and digital tools to be proactive and focused on adding value to your operations. We want the opportunity to partner with your technical personnel, and work side by side with you as an extension to your team, with a primary focus on creating and supporting value realization through actions.

Let’s talk about your current operations and the challenges you’re facing. Together, we can discover a path to improving your plant’s performance, focused on the KPIs that matter most to you and your stakeholders.

request a consultationConnect with us on LinkedIn for news, insights and related topics.

Did you know that your internet browser is out of date?

Your browser is out of date, and may not be compatible with our website.

Just click on the icons to download a compatible browser.

By closing this window you acknowledge that your experience on this website may be degraded.