Keep up with what’s new.

Connect with us on LinkedIn for news, insights and related topics.

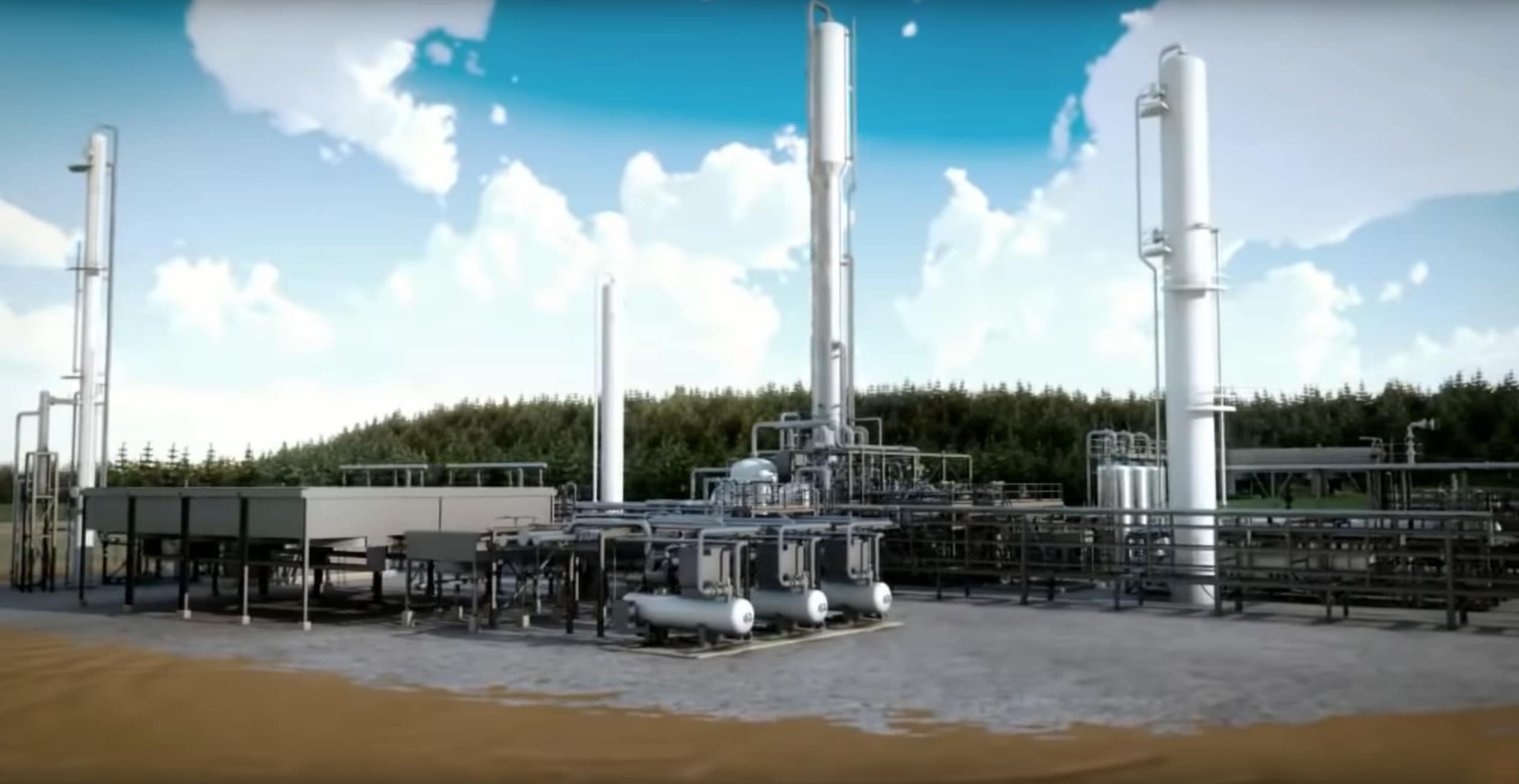

Increase high-value natural gas liquid (NGL) yields with Honeywell UOP Russell cryogenic units and fractionation technology

Time, money and flexibility are vital components of natural gas operations. UOP Russell cryogenic turboexpander (“cryo”) plants offer a faster path to profitability with flexible designs that can respond to shifting demands.

Streamlined Schedules

UOP modular gas processing plants are pre-engineered and fabricated in a controlled environment which streamlines project schedules. Due to the modular approach, your plant can be shipped by truck or barge – even to remote locations. Upon delivery to a prepared worksite, the equipment is ready to install. Modules are designed to fit together rapidly, significantly reducing site construction time, expense and associated delays. When combined with our turnkey services, we can get your system up and running quickly, so you can start making money faster.

Flexible Designs

Proven UOP Russell cryo plants can adjust to changing natural gas feed compositions and operate in ethane recovery or rejection mode based upon industry conditions and pipeline specifications. UOP Russell low flow solutions provide capacity flexibility that can adjust with unpredictable swings in production. UOP offers revamp solutions to upgrade your existing unit for increased recovery and/or rejection.

More Capacity with Higher Recovery

UOP Russell standard size cryogenic plants range from 40 MMSCFD to > 300 MMSCFD. The new UOP Russell SC30 is the first modular cryogenic gas plant capable of processing 300 million cubic feet-per-day. The SC30 delivers the highest production throughput, while providing the lowest capital costs and 20% more energy efficiency on a per cubic foot basis. Equipped with UOP Ortloff Recycle Split Vapor technology, the SC30 can recover more than 99% of high value ethane and propane for a higher return on investment.

UOP Russell Value:

The sooner your fractionation system is up and running, the sooner you can starts seeing profits. With delivery in as quick as 40 weeks, UOP’s NGL fractionation equipment is designed to make localized, distributed fractionation easy, fast and cost effective.

Proven UOP fractionation systems further separate ethane, propane, butane, isobutane and natural gasoline products from mixed natural gas and liquid streams. This portfolio includes the following columns with a broad range of capacities:

UOP expanded its solutions by developing a matrix of pre-engineered column designs with individual heat integration utilizing high capacity trays for separation of products. UOP trays are proven to increase separation performance, reduce capital and increase column capacity in a wide range of applications.

The number of columns and the exact process design is customized based on the raw-mix feed conditions and desired end products. With more than 800kbpd of installed fractionation experience, UOP can provide the right solution to meet your needs.

Connect with us on LinkedIn for news, insights and related topics.

Did you know that your internet browser is out of date?

Your browser is out of date, and may not be compatible with our website.

Just click on the icons to download a compatible browser.

By closing this window you acknowledge that your experience on this website may be degraded.